- Home

- News

Understanding Global Standards: The Essential Guide to Best Testing Electrical Safety Practices in Manufacturing

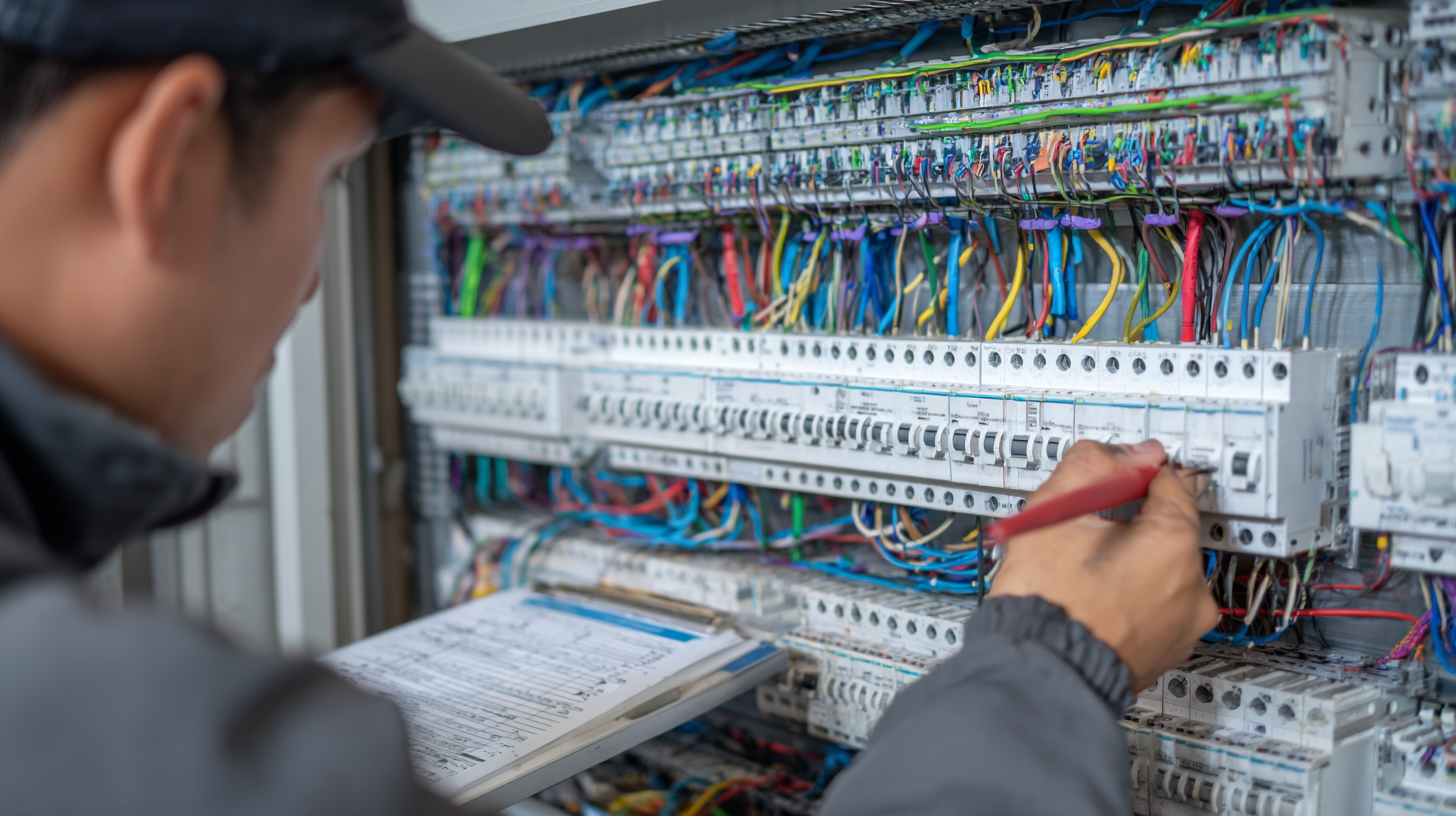

In the rapidly evolving landscape of manufacturing, the importance of adhering to global standards for Testing Electrical Safety has never been more critical. According to a recent report by the International Electrotechnical Commission, 50% of electrical incidents in industrial settings can be attributed to inadequate testing and compliance with safety protocols. As we look towards the technological advancements anticipated in 2025, from increased automation to the integration of artificial intelligence, manufacturers must prioritize robust electrical safety measures. The shift towards more sophisticated machinery and interconnected systems amplifies the need for rigorous testing to mitigate risks associated with electrical hazards. This guide aims to illuminate the best practices in Testing Electrical Safety, ensuring that manufacturers are not only compliant with current standards but also prepared for the challenges of the future.

In the rapidly evolving landscape of manufacturing, the importance of adhering to global standards for Testing Electrical Safety has never been more critical. According to a recent report by the International Electrotechnical Commission, 50% of electrical incidents in industrial settings can be attributed to inadequate testing and compliance with safety protocols. As we look towards the technological advancements anticipated in 2025, from increased automation to the integration of artificial intelligence, manufacturers must prioritize robust electrical safety measures. The shift towards more sophisticated machinery and interconnected systems amplifies the need for rigorous testing to mitigate risks associated with electrical hazards. This guide aims to illuminate the best practices in Testing Electrical Safety, ensuring that manufacturers are not only compliant with current standards but also prepared for the challenges of the future.

Key Global Standards for Electrical Safety in Manufacturing

Understanding global standards for electrical safety is crucial in manufacturing, especially as the market continues to expand rapidly. The global electrical safety footwear market is projected to grow significantly, reaching a value of $2.37 billion in 2024 and expected to hit $3.456 billion by 2025. This growth underscores the need for stringent electrical safety practices that align with best practices and industry standards.

Tips for Implementation: Ensure that all electrical safety gear, such as footwear, meets international safety standards. Regularly conduct safety audits to ensure compliance and maximize employee protection, as the right equipment can significantly reduce workplace accidents.

As companies navigate the evolving landscape of electrical safety regulations and manufacturing standards, embracing technologies and practices that ensure compliance can enhance operational efficiency. For instance, the global electrical equipment market is set to rise from $1,660.2 billion in 2025 to approximately $3,326 billion by 2032, with a compound annual growth rate (CAGR) of 10.4%. Investing in certified products not only ensures safety but also prepares businesses for future growth and innovation.

Tips for Staying Ahead: Keep abreast of industry trends and standards updates through continuous training and certification programs for your workforce. This proactive approach will foster a culture of safety and compliance while positioning your organization as a leader in the field.

Essential Best Practices for Testing Electrical Equipment

In today's manufacturing landscape, ensuring the electrical safety of equipment is paramount. The National Fire Protection Association (NFPA) reports that electrical failures and malfunctions are responsible for numerous fire incidents, leading to significant property damage and safety hazards. To mitigate these risks, adhering to essential best practices for testing electrical equipment is crucial. Regular testing and inspections should be integrated into the manufacturing process to not only comply with safety standards but also to enhance the longevity and reliability of electrical systems.

One key best practice involves implementing rigorous dielectric testing, which assesses an electrical insulation system's ability to prevent electrical leakage. According to a study by the Institute of Electrical and Electronics Engineers (IEEE), periodic dielectric testing can reduce the failure rate of electrical equipment by up to 35%. Moreover, utilizing advanced testing methods such as insulation resistance and ground testing can help identify potential weaknesses in equipment before they lead to catastrophic failures. By embracing these practices, manufacturers not only protect their assets but also foster a culture of safety that benefits workers and consumers alike.

Common Pitfalls to Avoid in Electrical Safety Testing

When it comes to electrical safety testing in manufacturing, understanding and avoiding common pitfalls is crucial for ensuring compliance and protecting workers. One of the significant challenges is overlooking the importance of proper equipment calibration. Regularly calibrating testing devices is essential, as inaccuracies can lead to false readings, ultimately compromising safety standards. Manufacturers should establish a routine schedule for calibration and ensure that all personnel are trained in proper testing techniques, thereby reducing human error.

Another frequent mistake is neglecting to keep comprehensive documentation of all safety tests and results. Failure to maintain accurate records can create gaps in safety protocols and make it difficult to demonstrate compliance during audits. A well-maintained documentation system not only serves as a reference for future testing but also builds a safer working environment by allowing manufacturers to spot trends and address recurring issues. Establishing a robust documentation process is vital for fostering accountability and maintaining high standards of electrical safety within manufacturing.

Understanding Electrical Safety Testing Practices

Implementing a Culture of Safety in Manufacturing Facilities

Creating a culture of safety in manufacturing facilities is paramount to ensuring the well-being of employees and compliance with global standards. Implementing safety practices begins with leadership commitment. When management actively promotes safety protocols and demonstrates their importance, it sets a precedent that resonates throughout the organization. Regular training sessions and safety meetings can foster open dialogues about safety concerns, empowering employees to prioritize safety in their daily operations.

Furthermore, integrating safety into the manufacturing process requires a proactive approach. This involves regular audits, risk assessments, and the establishment of clear safety procedures for equipment handling and electrical safety. Engaging employees in this process not only enhances their awareness but also encourages a sense of ownership over their work environment. By recognizing and rewarding safe practices, organizations can build a cohesive workforce dedicated to maintaining high safety standards. A well-informed and motivated team will naturally contribute to a safer manufacturing culture, ultimately leading to increased productivity and reduced accidents.

Understanding Global Standards: The Essential Guide to Best Testing Electrical Safety Practices in Manufacturing - Implementing a Culture of Safety in Manufacturing Facilities

| Testing Method | Description | Frequency | Responsible Party | Compliance Standards |

|---|---|---|---|---|

| Visual Inspection | Evaluating wires, connectors, and equipment for visible damage or wear. | Daily | Operators | IEC 60364 |

| Insulation Resistance Test | Measuring insulation effectiveness to prevent electrical leakage. | Monthly | Maintenance Team | IEEE 43 |

| Grounding System Test | Assessing the effectiveness of the grounding system. | Annually | Electrical Engineers | NFPA 70 |

| Leakage Current Test | Determining unwanted current paths to ensure safety. | Quarterly | Safety Officers | IEC 60990 |

| Functional Testing | Testing equipment to ensure it operates correctly under load. | Bi-Annual | Quality Control | ISO 9001 |

Future Trends in Electrical Safety Standards and Testing Methods

As the manufacturing landscape evolves, so do the electrical safety standards that govern industry practices. Future trends in electrical safety standards focus on integrating advanced technologies and methodologies that enhance the testing processes. Among these advancements is the incorporation of artificial intelligence and machine learning, which allows for more accurate predictions of potential failures and hazards. These technologies not only streamline the testing process but also significantly reduce human error, leading to increased safety and compliance with international standards.

Another trend is the emphasis on sustainability in electrical safety testing. Manufacturers are being encouraged to adopt eco-friendly materials and practices, aligning safety measures with environmental responsibility. This shift not only complies with emerging regulations but also meets the growing demand from consumers for greener manufacturing practices. Additionally, the rise of smart manufacturing systems is pushing for real-time monitoring and adaptive testing methods, ensuring that safety measures keep pace with innovations in electrical equipment. As these trends take hold, manufacturers must remain agile and proactive in adapting to the changing landscape of electrical safety standards.