- Home

- News

The Ultimate Guide to Mastering Electrical Check: Ensure Safety and Efficiency in Your Operations

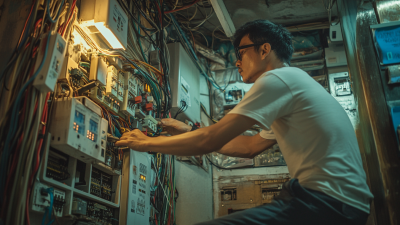

In the dynamic world of industrial operations, ensuring safety and efficiency is paramount, especially when it comes to electrical systems. A comprehensive Electrical Check is crucial, as studies show that approximately 30% of workplace accidents are caused by electrical failures, underscoring the pressing necessity for stringent inspection protocols. According to the National Fire Protection Association (NFPA), electrical malfunctions are responsible for over 45,000 reported fires annually in the United States, leading to extensive property damage and tragic loss of life. The importance of mastering the Electrical Check process cannot be overstated; not only does it safeguard personnel and assets, but it also minimizes downtime and enhances overall operational productivity. This guide aims to equip you with the knowledge and tools necessary to conduct effective electrical inspections, ensuring that you mitigate risks and optimize performance in your operations.

Understanding the Importance of Electrical Safety Checks in Operations

Understanding the importance of electrical safety checks in operations is paramount for ensuring both the safety of personnel and the efficiency of systems. Electrical hazards can lead to severe accidents, property damage, and costly downtime. Regular safety checks help identify potential risks such as faulty wiring, outdated equipment, or inadequate safety measures before they escalate into hazardous situations. By prioritizing these checks, organizations can create a safer workplace and foster a culture of safety among employees.

Incorporating thorough electrical safety checks into operational protocols not only mitigates risks but also enhances overall operational efficiency. Well-maintained electrical systems function optimally, reducing the likelihood of unexpected failures and the associated productivity losses. Moreover, compliance with safety regulations can prevent legal issues and fines, further emphasizing the financial benefits of these checks. By investing in regular electrical safety assessments, businesses not only protect their workforce but also optimize their operational capabilities, leading to improved performance in the long run.

The Importance of Electrical Safety Checks in Operations

Regular electrical safety checks are crucial for maintaining operational safety and efficiency. The chart above illustrates the number of various electrical checks conducted on a weekly basis in different categories, highlighting their importance in ensuring compliance and risk management in electrical operations.

Key Components of an Effective Electrical Safety Checklist

An effective electrical safety checklist is crucial for ensuring both safety and operational efficiency in any workplace. According to the National Fire Protection Association (NFPA), electrical failures are a leading cause of workplace incidents, accounting for approximately 10% of all workplace fires. A comprehensive checklist can help identify potential hazards before they lead to accidents. Key components should include inspections of wiring, circuit breakers, and grounding systems, along with verifying that all equipment meets safety standards.

Tip: Regularly update your checklist based on recent safety audits and technological advancements to keep your operations compliant with industry regulations.

Another vital aspect of an electrical safety checklist is the inclusion of personal protective equipment (PPE) requirements. The American National Standards Institute (ANSI) recommends that teams assess the need for PPE tailored to specific electrical tasks to mitigate exposure to hazards. Training staff on the proper use of PPE and emergency protocols should also be a checklist staple, as informed employees can significantly reduce risk.

Tip: Schedule training sessions quarterly to reinforce safety protocols and ensure all team members understand the checklist procedures thoroughly.

Step-by-Step Guide to Conducting Electrical Inspections

When it comes to ensuring safety and efficiency in electrical operations, conducting thorough electrical inspections is paramount. A systematic approach to these inspections not only helps in identifying potential hazards but also ensures compliance with safety regulations. Start by gathering the necessary tools, such as insulation resistance testers and multimeters, which are essential for assessing the integrity of electrical systems.

Begin your inspection by examining the main components, including circuit breakers, wiring, and connections. Look for signs of wear, corrosion, or overheating, as these can indicate underlying problems. It is also critical to check grounding systems, as inadequate grounding can lead to serious electrical faults. After the initial visual inspection, proceed to test the electrical systems systematically while documenting your findings. Use this data to create an action plan for any repairs or upgrades needed, ensuring that your operations not only meet industry standards but also prioritize safety for all personnel involved.

Common Electrical Hazards and How to Identify Them

Electrical hazards can pose serious risks in any operational environment. Understanding common electrical hazards and knowing how to identify them can significantly enhance safety and efficiency. Some prevalent hazards include overloaded circuits, exposed wires, and improper grounding. Regularly inspecting electrical equipment and connections ensures that issues are detected early, preventing accidents and equipment failures.

**Tip:** Always check for frayed wires or loose connections before turning on electrical equipment. Using a voltage tester to confirm that circuits are not live before performing maintenance can protect you from electric shock.

Furthermore, be vigilant about the signs of potential hazards, such as flickering lights or frequent circuit breaker trips. These can indicate underlying electrical problems that need urgent attention. Regular training for employees on how to recognize these hazards creates a safety-oriented work culture.

**Tip:** Encourage employees to report any unusual electrical issues immediately. Having a checklist for routine electrical inspections can aid in identifying risks before they escalate into significant problems.

The Ultimate Guide to Mastering Electrical Check: Ensure Safety and Efficiency in Your Operations - Common Electrical Hazards and How to Identify Them

| Hazard | Description | Symptoms | Prevention | Identification Method |

|---|---|---|---|---|

| Electrical Shock | Contact with live electrical parts can cause injury or death. | Tingling sensation, burns, unconsciousness. | Use insulated tools and wear appropriate PPE. | Regular inspections of equipment and wiring. |

| Overloaded Circuits | Exceeding the maximum current rating of a circuit. | Tripped breakers, flickering lights, warm outlets. | Distribute load evenly and upgrade circuit as needed. | Monitoring of circuit load and breaker performance. |

| Arc Flash | A dangerous release of energy from an electrical fault. | Hearing a loud bang, seeing a flash, burns. | Proper training and use of protective gear. | Regular hazard analysis and maintenance checks. |

| Electrical Fires | Fires caused by faults in electrical equipment or overloading. | Smoke, flames, scorch marks on materials. | Use the correct fuses and avoid frayed wires. | Periodic inspection of wiring and devices. |

Best Practices for Maintaining Electrical Safety Compliance

Maintaining electrical safety compliance is crucial for any operation looking to enhance safety and efficiency. A well-structured approach not only protects personnel but also safeguards equipment from potential hazards.

The first step is to conduct regular inspections of all electrical installations. This includes checking for wear and tear, ensuring grounding systems are intact, and verifying that circuit breakers and fuses are functioning properly.

The first step is to conduct regular inspections of all electrical installations. This includes checking for wear and tear, ensuring grounding systems are intact, and verifying that circuit breakers and fuses are functioning properly.

In addition to routine inspections, implementing training programs for employees can significantly improve safety practices. Educating staff on recognizing electrical hazards and understanding the importance of using protective gear is vital. It's essential to establish a culture where safety is prioritized, and all personnel feel empowered to report any concerns.

Lastly, maintaining up-to-date documentation of all compliance checks and maintenance activities is key to ensuring ongoing safety. This not only serves as a record for audits but also aids in identifying areas for future improvement. By adhering to these best practices, organizations can foster a safer working environment while boosting operational efficiency.

Related Posts

-

The Comprehensive Guide to Mastering Electrical Check for Global Procurement

-

2025 Electrical Equipment Innovations: Essential Checklist for Global Buyers

-

How to Ensure Safety with Your Home Electrical Check Process

-

Maximizing Success in Global Trade by Checking Electrical Equipment at the 137th Canton Fair

-

Navigating International Trade Certifications for Optimal Electrical Testing Safety

-

5 Reasons Why Best Testing Wires For Power Enhance Efficiency and Safety in Electrical Systems