- Home

- News

5 Reasons Why Best Testing Wires For Power Enhance Efficiency and Safety in Electrical Systems

In today's rapidly evolving electrical landscape, the importance of reliable testing wires for power cannot be overstated. According to a recent report by the International Electrotechnical Commission (IEC), nearly 30% of electrical system failures are attributed to inadequate testing and maintenance practices. This statistic emphasizes the critical role that high-quality testing wires play in enhancing both the efficiency and safety of electrical systems. By ensuring proper connectivity and accurate measurements, the best testing wires for power not only help prevent system malfunctions but also contribute to significant cost savings through reduced downtime and maintenance needs. As the demand for energy efficiency grows, adopting robust testing practices becomes essential for industry professionals aiming to uphold safety standards and optimize performance in complex electrical environments.

Choosing the Right Testing Wires: A Key Component for Efficiency

Choosing the right testing wires is crucial for enhancing the efficiency and safety of electrical systems. According to a report by the International Electrotechnical Commission (IEC), approximately 30% of electrical failures can be traced back to inadequate testing practices. High-quality testing wires ensure accurate diagnostics and safety checks, minimizing the risk of system downtime and costly maintenance. With advancements in materials and technology, modern testing wires are designed to withstand higher voltages and currents, ensuring reliable performance even in the harshest conditions.

Moreover, the National Electrical Manufacturers Association (NEMA) highlights that using subpar testing wires can compromise not only the system's reliability but also its longevity. Inadequate wiring can lead to overheating, increased resistance, and ultimately, failure of critical components. By investing in top-grade testing wires, electrical engineers can significantly reduce the potential for accidents and equipment failures, leading to a healthier, more efficient electrical infrastructure. Ultimately, choosing the right testing wires is an investment that pays off in both performance and safety.

Understanding the Importance of Quality in Electrical Testing Wires

In the realm of electrical systems, the significance of quality testing wires cannot be overstated. High-quality testing wires play an essential role in ensuring the efficiency and safety of electrical installations. When electrical systems are tested with inferior wires, the risk of inaccurate readings increases, which can lead to improper assessments and, ultimately, hazardous conditions. Quality testing wires are designed to withstand various environmental challenges and electrical loads, thereby providing reliable performance during diagnostics.

Moreover, investing in superior testing wires fosters a culture of safety within electrical engineering practices. Quality wires are equipped with features such as enhanced insulation and durable materials that reduce the risk of short circuits and electrical failures. As professionals carry out their assessments, the assurance of using reliable testing tools facilitates a more thorough understanding of the system's integrity. In this way, the importance of quality in electrical testing wires transcends mere functionality, becoming a fundamental component of safe electrical operations.

5 Reasons Why Best Testing Wires For Power Enhance Efficiency and Safety in Electrical Systems

Enhancing Safety: How Best Testing Wires Reduce Electrical Hazards

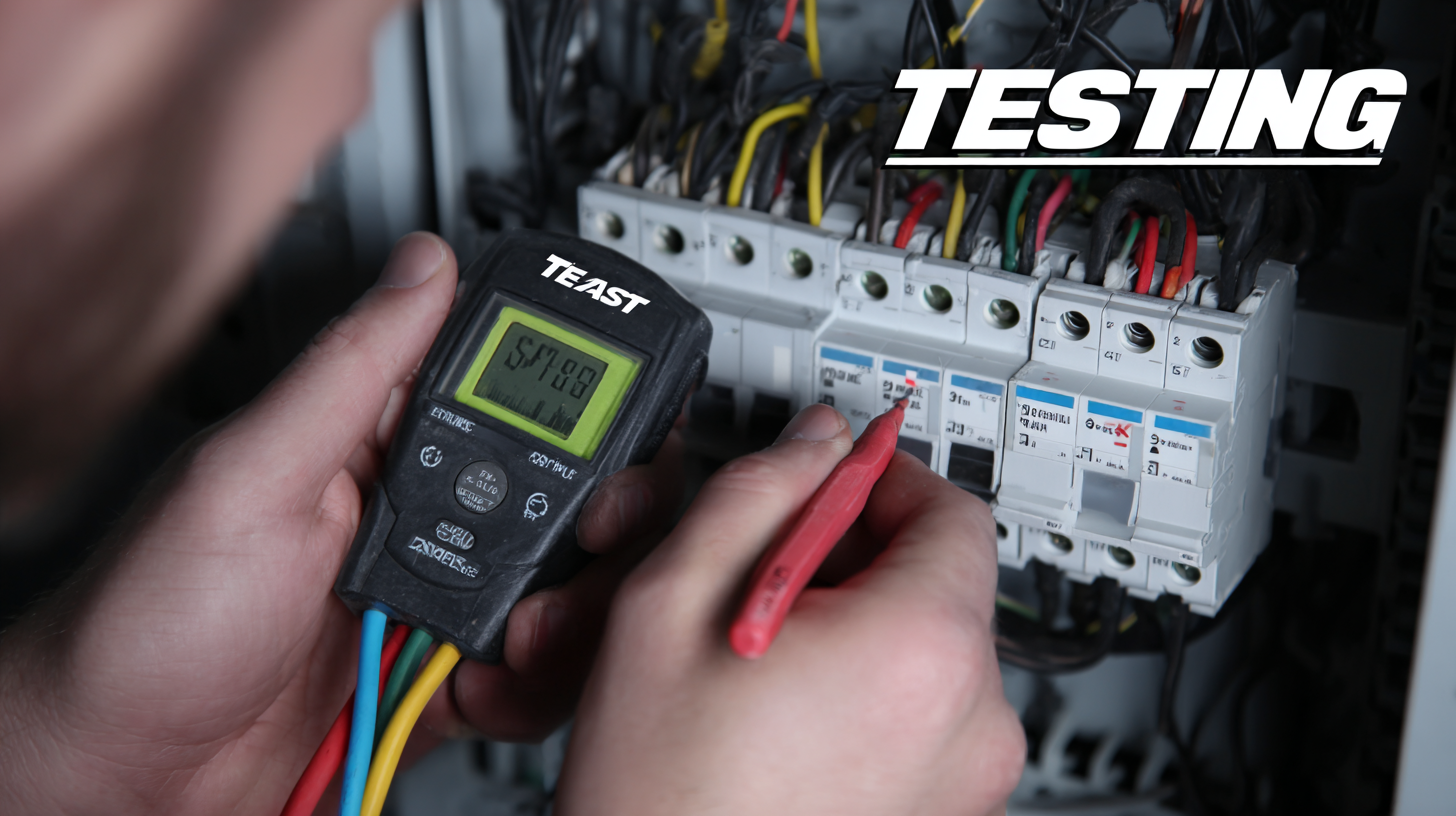

When it comes to maintaining the safety and efficiency of electrical systems, the choice of testing wires plays a crucial role. High-quality testing wires are designed to withstand high voltages and temperatures, significantly reducing the risk of electrical hazards. By using the best testing wires, technicians can minimize the chances of short circuits, overheating, and other potentially dangerous situations. These wires often come with superior insulation and durability, providing an added layer of protection against wear and damage.

To enhance safety, technicians should regularly inspect their testing wires for any signs of damage or wear. This simple practice can prevent unforeseen electrical hazards that could arise from frayed wires or exposed conductors. Additionally, always ensure that the testing wires you use are rated for the specific application; using the correct wire types and gauges can make a significant difference in preventing failures.

Another key tip is to utilize color-coded wires for different testing purposes. This not only helps in maintaining organization but also significantly reduces the risk of accidental mix-ups that could lead to dangerous situations. By following these tips and using the best testing wires, electrical systems can be managed with enhanced safety, ultimately benefiting both technicians and end-users.

Boosting System Performance Through Proper Wire Selection

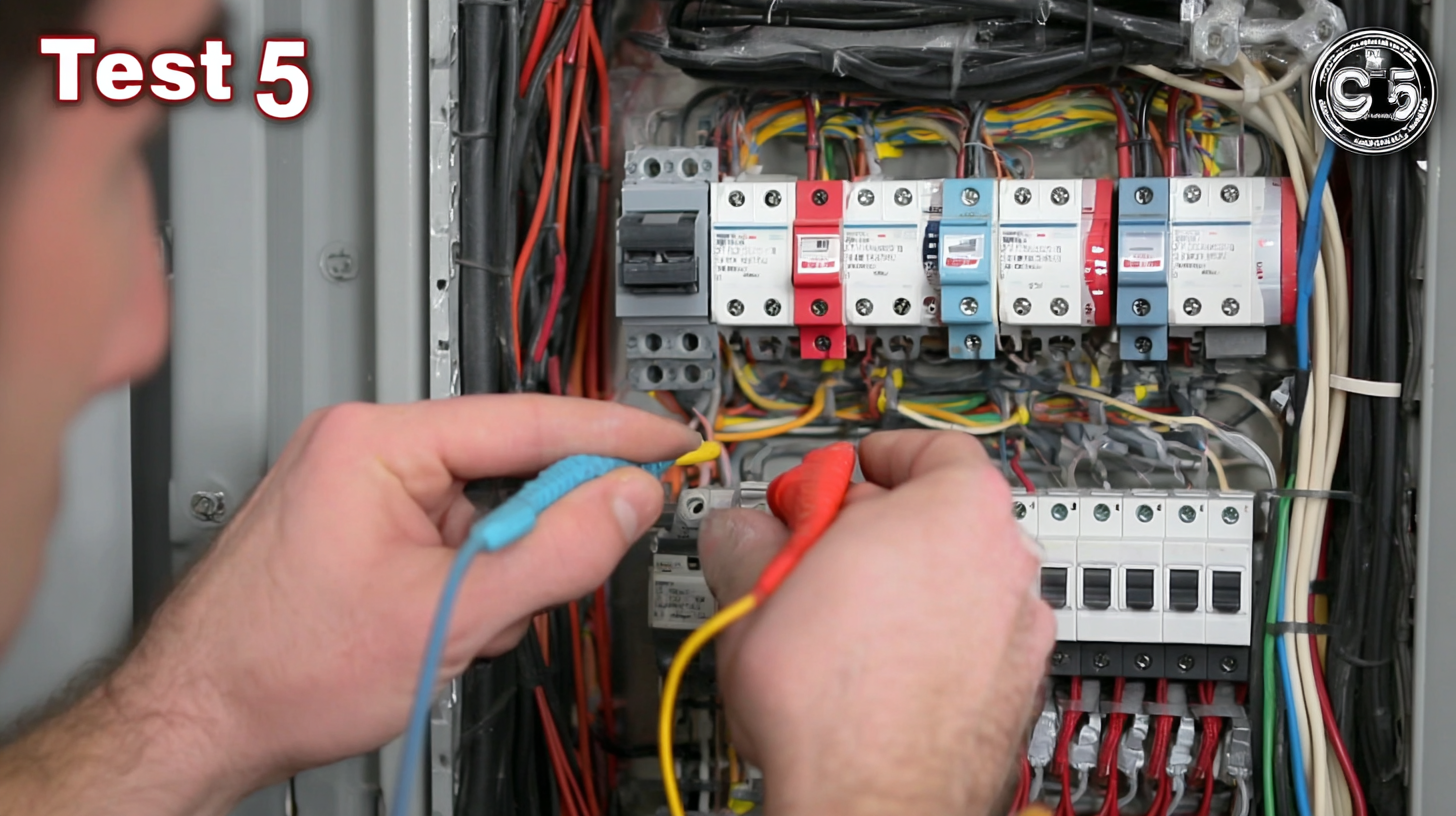

Proper wire selection is crucial for maximizing the performance of electrical systems. By choosing the best testing wires for power, you not only enhance the efficiency of your system but also ensure safety during operation. High-quality wires are designed to handle specific loads without overheating or experiencing voltage drops, thereby maintaining optimal performance and prolonging the life of electrical components.

Additionally, the right testing wires provide accurate feedback during diagnostics and maintenance. This accuracy allows for better monitoring of system performance, helping to identify potential issues before they escalate into significant problems. By focusing on proper wire selection, you create a more reliable electrical infrastructure that supports both short-term efficiency and long-term sustainability.

5 Reasons Why Best Testing Wires For Power Enhance Efficiency and Safety in Electrical Systems - Boosting System Performance Through Proper Wire Selection

| Reason | Description | Impact on Efficiency | Impact on Safety |

|---|---|---|---|

| High Conductivity | Using wires with better conductivity reduces energy loss during transmission. | Increased energy efficiency leads to lower operational costs. | Lower resistive heating decreases fire hazards. |

| Durability | High-quality materials withstand environmental stresses, preventing wear and tear. | Longer lifespan reduces replacement frequency, saving costs. | Resists damage, which enhances overall system safety. |

| Proper Insulation | Well-insulated wires prevent accidental electrical contact and shorts. | Ensures maximum system efficiency by reducing faults. | Diminishes risk of shock and fire incidents. |

| Size and Gauge Selection | Choosing the right wire size minimizes energy losses and overheating. | Optimizes current flow leading to efficient performance. | Reduces risks related to overloading and potential fires. |

| Testing and Quality Assurance | Regular testing ensures wires perform as expected under load. | Identifying issues early maintains optimal performance. | Proactive measures reduce the likelihood of catastrophic failures. |

Maintenance Tips for Prolonging the Life of Testing Wires in Electrical Systems

When it comes to electrical systems, the longevity of testing wires is crucial for maintaining their efficiency and safety. Regular maintenance practices can significantly prolong the life of these wires, ensuring reliable performance over time. One fundamental tip is to conduct routine inspections for any signs of wear or damage, such as fraying or exposed conductors. Promptly addressing these issues can prevent more severe problems down the road. Additionally, using protective covers or conduits can shield wires from environmental hazards and physical abrasions that could compromise their integrity.

Another important aspect of maintenance is proper storage. When not in use, testing wires should be coiled neatly and stored in a dry, clean environment to avoid tangling and moisture-related damage. Keeping them organized not only extends their lifespan but also enhances accessibility for future use. Furthermore, always ensure you are using the appropriate wire for the specific application, as this will contribute to both performance and safety. By prioritizing these maintenance tips, professionals can enhance the reliability of their electrical systems and mitigate the risks associated with faulty testing wires.