- Home

- News

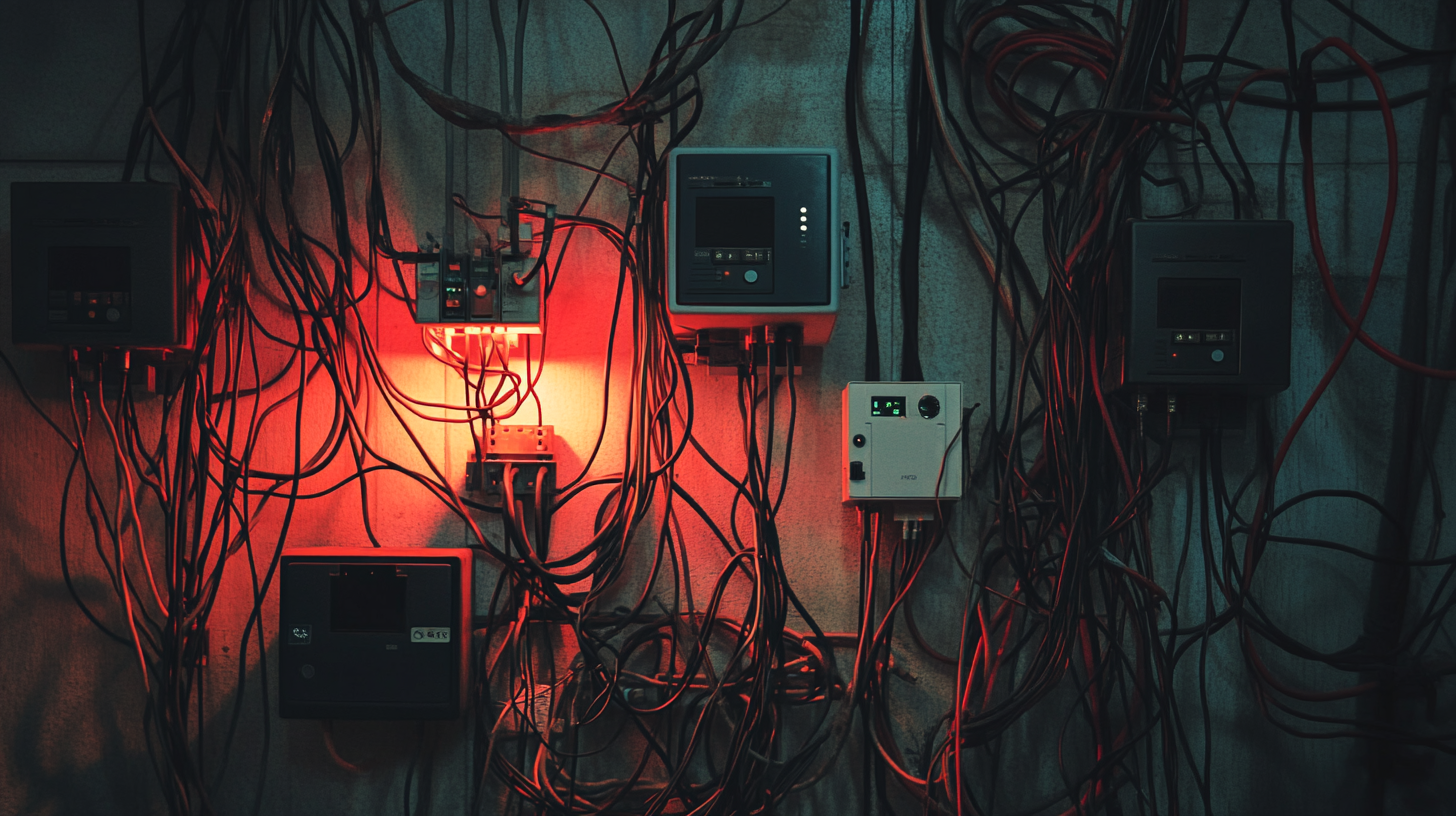

5 Essential Tips for Conducting an Electrical Installation Check

Today, setting up electrical systems safely and reliably can be more critical than ever. The National Fire Protection Association (NFPA) reports that electrical failures are estimated to account for 22% of all reported house fires, while such fires lead to injuries, fatalities, and the destruction of property. Such alarming statistics show how vital it is to run checks for electrical installations in order to determine that the wiring, outlets, and devices conform to safety standards applied nationally. On the other hand, running thorough inspections periodically can soon tell of possible dangers that can protect lives and assets.

Besides, the International Electrotechnical Commission (IEC) also holds that faulty installation of electricals means malfunction, inefficiency, and obviously, high repair charges. According to one recent report, firms neglecting electrical installation checks accrue maintenance costs that go 30% over average for the same, thus, putting in place a formal procedure for electrical installation checks not only improves safety but also operational efficiency. This blog aims to highlight five important tips for conducting an electrical installation check to protect your property and approach compliance with electrical standards.

Key Preparations Before Starting an Electrical Installation Check

An effective electrical installation check should start by preparing well. It should help ensure that the safety standards are in adherence while making the inspection process more efficient. Gather all the necessary papers, such as blueprints of the installation, previous inspection reports, as well as related codes and regulatory documents. Familiarity with these documents will give a holistic idea of the design and modifications if any, made since the last inspection. Next, gather tools and personal protective equipment (PPE). Consider voltage testers, multimeters, and circuit analyzers necessary for accurate assessment regarding the electrical system's static performance. Non-negotiable PPE, such as gloves and safety glasses, must be worn for protection against potentially harmful exposure ahead of an inspection. Put great emphasis on organizing an area of work such that it minimizes distractions as this not only helps focus but also systematizes the approach to the check. Scheduling an inspection during one of those periods when the electrical system has minimal load is also a prudent measure. In this way, a precise and detailed examination can be achieved while the chances of meddling caused by appliances in operation are quite low. Inform competent authorities about the inspection schedule to make them aware and prepared. Following these preparatory measures forms a foundation for an effective and successful check on an electrical installation.

Identifying Common Electrical Hazards to Look For

Most significantly, however, it allows one to reason with such dangers and promises that no legislation and norms will come in the way of electrical installation inspection. Commonly available things that really threaten safety in an electrical installation check include exposed wires-another very potential source of a short circuit or electrocution. It is necessary to sweep every socket, junction box, and wiring to determine whether it is actually insulated and secured properly. If any wire is frayed or has any sign of damage, it immediately needs to be replaced so there is no chance of disaster.

Overloaded circuits are another common thing to always look for. Count the number of appliances connected to a single outlet or circuit. Whenever a circuit gets overcrowded, it will always overheat and eventually cause a fire. Check the load within which the circuit operates using a circuit tester, and if necessary, redistribute devices to other circuit lines. Check outlets for proper grounding as well. Unstable ground adds the risk of electrical shock and should be corrected to improve safety.

Not forgetting, however, that most of all appraisals are supposed to be done on the premise of being overall proof that all electrical installations were as per local code and standards. Inspections should include the verification of the application of adequate materials and safety measures. This, in turn, aids hazard identification but also makes it safer for everyone involved in using the electrical system. As detailed as checking can be, it will considerably reduce risks and be part of an even safer electrical installation.

Understanding Compliance Standards and Regulations

Familiarity with compliance standards and regulations really is important-they help installations not only to meet safety requirements, but also adherence to local codes for property and its occupants. In brief, such an understanding is gained through studying national and local standards like NEC in the U.S. or IET Wiring Regulations in the U.K. A must for any electrician or inspector, frequent checking for updates to codes and regulations that can change often will also influence the best practices in installation.

Compliance is not just a checkbox with some good understanding of how these standards are in the particular environment. For example, specific features of installations including criteria of compliance - say, different distinctions between residential environments and commercial ones are inherent in such meanings. Grounding and circuit protection, as well as proper labeling - will be inspection areas since they are essential to fulfilling regulatory requirements. Moreover, making sure that all materials and equipment conform to industrial standards is just as vital in the safety and integrity of the electrical system.

It also comprises thorough documentation of standards compliance during the actual installation check. Any record of inspection, modification, or approval will protect the installer and owner against any adverse claims resulting from inspections done by regulatory bodies or from claims by the property owner. Therefore, by conducting a complete electrical installation check, supported by solid knowledge of compliance, safety can be the most increased and made as reliable as can get for the electrical works.

Essential Tools and Equipment for Effective Inspections

You are trained on data up to October 2023. The importance of the right tools of the right equipment when it comes to conducting checks on electrical installations cannot be overstated. Essential tools include the common-used multimeter, clamp meter, and voltage tester to safely measure an electrical system's operation. Multimeters measure voltage, current, and resistance for a complete view of the system's condition. A clamp meter measures current without breakage of a wire, thus saving time on inspection.

Of course, the basic tool kit would not be complete without personal protective equipment (PPE). The nature of inspection sometimes demands that personnel work in potentially hazardous environments. It is thus, extremely important, therefore, that PPE is worn, including insulated gloves and safety goggles. Because these devices can tell a person where the hotspots are in electrical connections, they will use thermal imaging cameras to find out about problems before they get out of hand. Thus, equipping oneself with the barest essential tools and being converted to a safety first mindset improves electrical installation checks.

Documenting Findings and Recommendations for Future Reference

All information gathered and documented during electrical installations helps in providing an assurance of safety and compliance. Proper records kept during an inspection provide a way for professionals to indicate issues, corrective actions taken, improvement on future installations, etc. Every detail included—from the wiring state to any safety violation—helps the engineer in creating a thorough record that becomes a valuable asset to future personnel.

A well-structured approach would facilitate ease of communication among team members and all stakeholders involved in the process. It is recommended that templates or digital means to simplify the recording of findings be used. Adding images and diagrams to reports allows for more effective communication. The importance of this has relevance at a time when internal threats are being discussed across industries; companies have to guard against malicious actions, while they must also be aware of unintentional faults which may lead to serious safety issues.

Likewise, when recommendations derived from inspection results are clearly defined, accountability increases. Recommendations should, therefore, not only address the immediate problems discovered but also encourage best practice for the future. As established by various recent studies on the credibility of suggestions generated through Artificial Intelligence, the considerations offered should be put under firm scrutiny. Through maintained human oversight, the Fire31 processes are effectively assisted by technology, while the final say in terms of safety and compliance is still in the hands of trained professionals.