- Home

- News

Future of Electrical Testing: 2025 Tech Trends in Wire Continuity Solutions

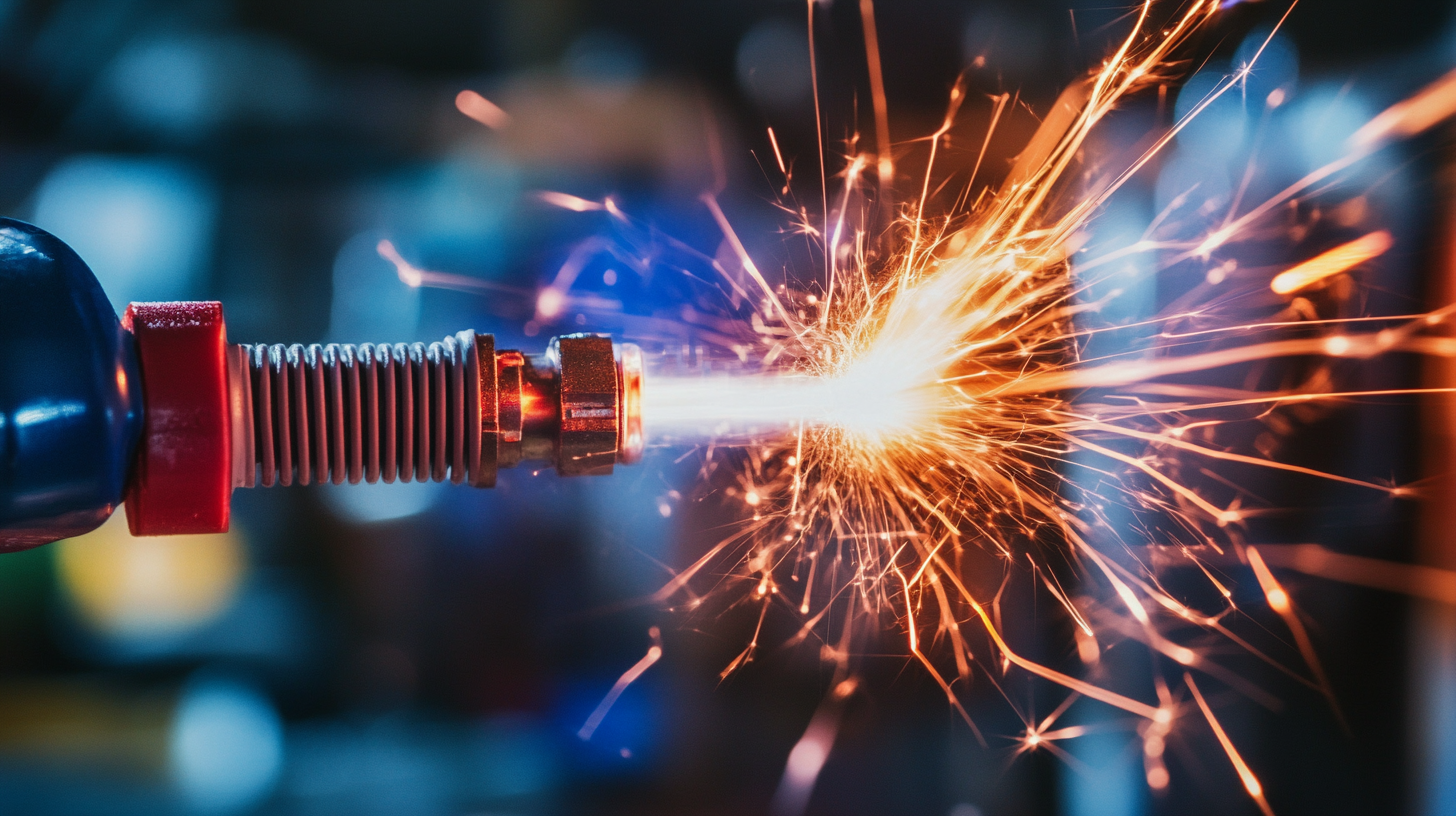

In the rapidly evolving landscape of electrical testing, the significance of Testing Wire Continuity is more pronounced than ever as we approach 2025. With the increasing complexity of electrical systems, ensuring seamless and reliable wire connections is paramount. As innovations in technology emerge, they pave the way for more advanced solutions that not only enhance the efficiency of testing processes but also improve accuracy and reliability. This blog will explore the pivotal trends shaping wire continuity solutions and how they are set to redefine the industry in the coming years.

As we look ahead, several key technological advancements promise to transform the traditional methods of Testing Wire Continuity. From smart automation and artificial intelligence to the integration of IoT devices, these innovations are anticipated to streamline testing protocols, reduce human error, and provide real-time monitoring capabilities. Embracing these trends will empower engineers and technicians to tackle the challenges of modern electrical systems with ease, ensuring safety and performance at every level. Join us as we delve into the future of electrical testing and the exciting developments that lie ahead.

Emerging Technologies Reshaping Wire Continuity Testing in 2025

As we approach 2025, the landscape of wire continuity testing is on the verge of transformation, driven by emerging technologies that promise to enhance accuracy, efficiency, and ease of use. One notable advancement is the integration of artificial intelligence (AI) and machine learning, which are being utilized to develop smarter testing devices. These innovations allow for real-time analysis of continuity results, automatically identifying issues and suggesting corrective actions. This evolution not only reduces the time technicians spend on manual data interpretation but also minimizes human error. Another trend reshaping wire continuity solutions is the rise of cloud-based monitoring systems. With the ability to remotely access testing data and system performance metrics, professionals can now manage their electrical systems from anywhere, ensuring heightened oversight and quicker response times. This shift also enables collaborative problem-solving, where teams can analyze data together, regardless of their physical location, enabling more comprehensive solutions to emerging issues. Additionally, the adoption of advanced materials and more flexible wiring designs is influencing continuity testing methods. New wire compositions are not only more resilient but also provide enhanced performance under extreme conditions. As these materials become prevalent, testing protocols will need to adapt, ensuring that all testing equipment can accurately assess the integrity of these innovative products. Overall, these emerging technologies are set to revolutionize how wire continuity testing is approached, ensuring safer and more reliable electrical systems in the future.

The Role of AI and Automation in Electrical Testing Solutions

As we approach 2025, the landscape of electrical testing is set to undergo a significant transformation driven by advancements in AI and automation. These technologies are becoming pivotal in enhancing wire continuity solutions, moving beyond traditional methods toward more sophisticated and efficient systems. The integration of AI facilitates real-time diagnostics and predictive maintenance, allowing engineers to identify issues before they escalate, ultimately ensuring safer and more reliable electrical installations.

Moreover, the commitment of substantial investments in the energy sector signals a growing recognition of the need for innovation. By advancing automation technologies, businesses can optimize their operations and reduce human error in testing processes. This shift not only boosts efficiency but also creates new job opportunities, reflecting a forward-looking approach to workforce development. With the intersection of automation and AI, industries are encouraged to adopt a collaborative mindset, enhancing the resilience and adaptability of electrical testing practices to meet modern demands.

The embrace of these emerging technologies aligns with the broader vision of Industry 5.0, where the synergy between digital solutions and traditional manufacturing processes will redefine operational paradigms. Through interconnected systems, businesses can cultivate a more agile environment, paving the way for a future where electrical testing is as innovative as the technologies it supports. As we look ahead, the potential for AI and automation in electrical testing solutions promises not only improved efficiency but also a more sustainable and responsive energy landscape.

Advancements in Wire Continuity Tools for Enhanced Accuracy

The advancement of technology has significantly transformed various aspects of electrical testing, with particular emphasis on wire continuity solutions. As we approach 2025, the latest innovations in continuity tools promise to enhance accuracy like never before. Modern devices are increasingly equipped with intelligent sensors and algorithms that allow for real-time diagnostics, reducing human error and increasing reliability in testing processes.

One of the most notable trends is the integration of IoT technology into wire continuity tools. This connectivity enables the devices to not only perform tests but also to communicate results instantly with other systems, providing detailed reports for better data analysis and decision-making. Furthermore, automation in testing procedures means that processes that once required extensive manual input can now be completed with minimal intervention, streamlining workflows and improving efficiency across various sectors.

Additionally, the focus on user-friendly interfaces is paving the way for widespread adoption of these advanced tools. Enhanced graphical displays and simplified controls are making continuity testing more accessible to technicians at all skill levels. As a result, organizations can expect reduced training times and increased productivity without compromising on the accuracy of their electrical testing procedures. These innovations signal a promising future for wire continuity solutions, ultimately leading to safer and more efficient electrical systems.

Sustainability Trends in Electrical Testing and Wire Solutions

In the rapidly evolving landscape of electrical testing, sustainability is becoming a crucial consideration for wire continuity solutions. As industries seek to minimize their environmental impact, the methods and materials used in electrical testing are undergoing significant transformations. The shift toward green technologies means that manufacturers are now focusing on eco-friendly materials that not only improve performance but also reduce carbon footprints. By adopting sustainable production practices, companies are able to create wire solutions that align with global sustainability goals.

Moreover, advancements in technology are paving the way for smarter testing solutions. Innovations in digitalization and automation are enhancing the efficiency of wire continuity testing, enabling real-time monitoring and diagnostics. These technologies not only ensure compliance with international standards but also promote the reuse and recycling of materials in testing processes. By integrating sustainable practices into electrical testing, organizations can contribute to a circular economy, reducing waste and extending the lifecycle of products.

Additionally, the industry is seeing a rise in collaborative efforts aimed at promoting sustainability. Stakeholders from various sectors are coming together to share knowledge and resources, fostering a culture of innovation. This collaboration is essential in developing effective standards and practices that prioritize environmental responsibility. As we move toward 2025, it is clear that the future of electrical testing will not only be defined by technological advancements but also by a collective commitment to sustainability in wire solutions.

Future Challenges and Opportunities in Electrical Testing Technologies

In the ever-evolving landscape of electrical testing, the challenges and opportunities presented by advancements in wire continuity solutions are particularly salient as we approach 2025. According to a report by MarketsandMarkets, the global electrical testing market is projected to reach $6.6 billion by 2025, driven primarily by the increasing demand for safety and reliability in electrical installations. This presents a significant opportunity for organizations to innovate their testing methodologies and adopt next-generation technologies that enhance efficiency and accuracy.

One of the critical challenges in electrical testing is the integration of automation and artificial intelligence into traditional testing processes. A survey by Grand View Research indicates that technological advancements, including AI and machine learning, could reduce testing time by up to 30%. However, the transition requires not only investment in new technologies but also a paradigm shift in workforce skills and knowledge. As companies adapt, there will be an increasing need for trained personnel who can leverage these advanced tools effectively.

Moreover, sustainability is emerging as a central theme in electrical testing technologies. The adoption of eco-friendly materials and practices is no longer optional; it is becoming a regulatory imperative. According to a recent study by the International Electrotechnical Commission, about 60% of electrical testing organizations are now prioritizing sustainability in their operational strategies, signaling a shift toward greener practices. This focus not only meets regulatory demands but also attracts environmentally conscious consumers and clients, making it a dual opportunity for businesses looking to innovate while adhering to social responsibility.